WE PRINT BONE™

Interested? Get in touch with us to learn more about your opportunities.

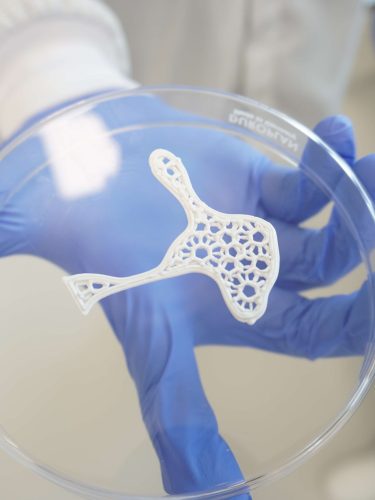

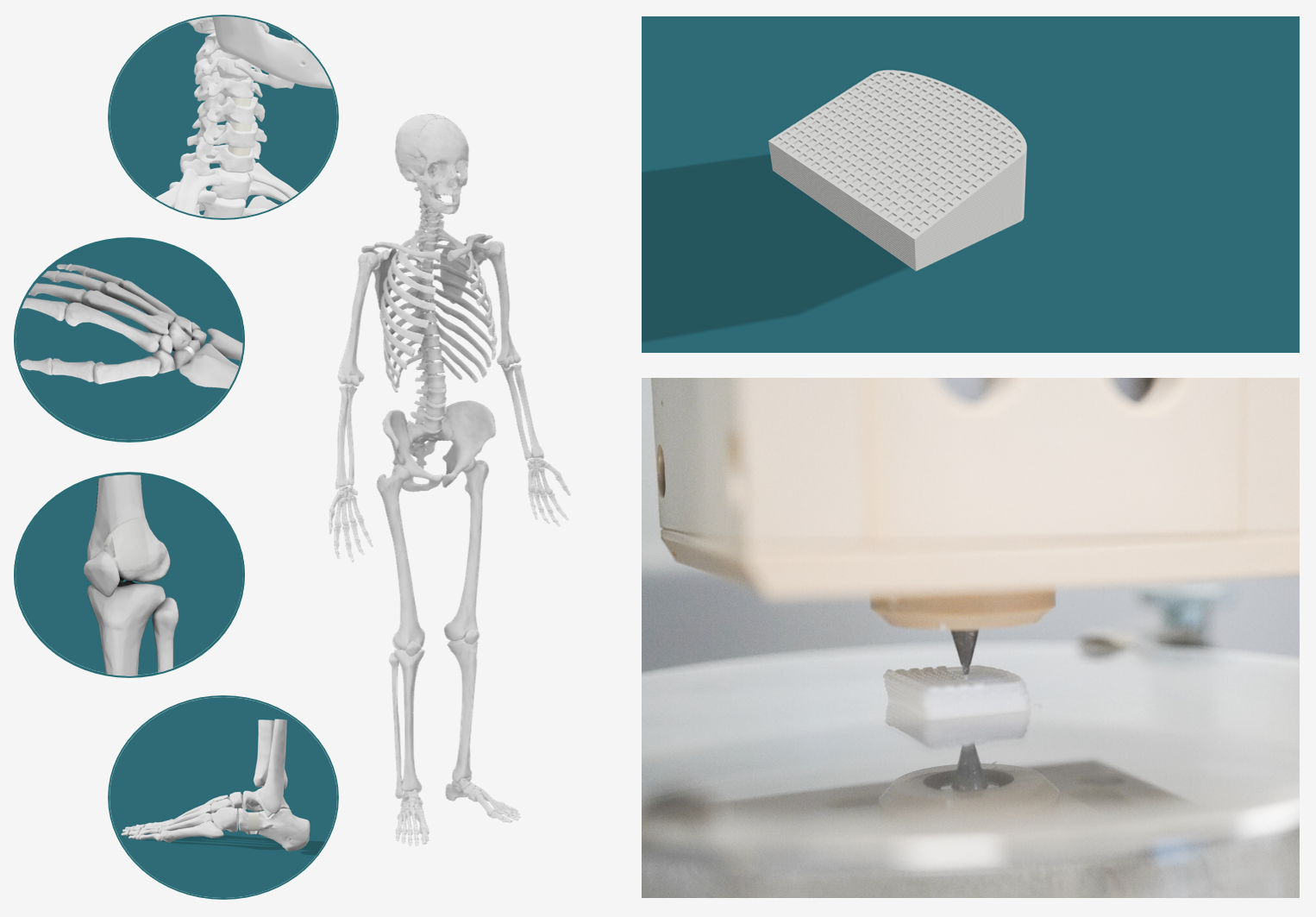

Osteotransductive and structural bone implants

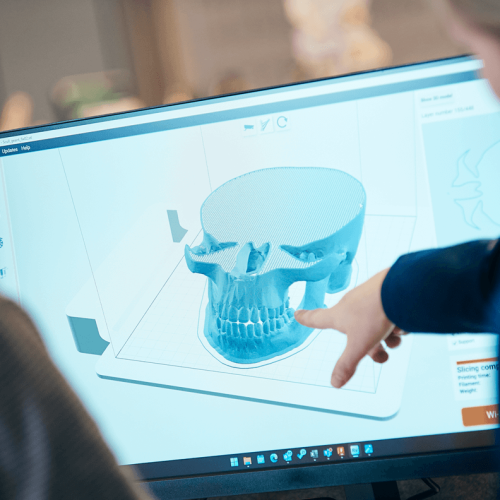

Ossiform® provides resorbable patient-matched bone implants that provide structure while facilitating the natural forming of new bone.

In short: We Print Bone™.

Made from pure 3D printed ß-tricalcium phosphate, the P3D Bone offers a resorbable material with tailored properties, optimized for bone regeneration and indication-specific biomechanical thresholds.

About Ossiform®

We are continuously working to redefine bone replacements through progressive research and close collaboration with physicians and industry partners. Our patient-centric approach and commitment to innovation, quality, and progress steer our efforts to provide best-in-class implant solutions that facilitate the natural forming of new bone.

Company video

Get to know Ossiform®

P3D Scaffolds

See our latest news

Ossiform® Presentation at LSI USA ’24

CELLINK and Ossiform® Enter a Strategic Partnership to launch Ossi Ink, a printable bioink based on Ossiform®’s P3D Bone material

Ossiform® raises new capital

CAM Bioceramics and Ossiform® team up for OMTEC 2022

Ossiform® – Announces rebrand

Patent for Ossiform®’s technology granted in China

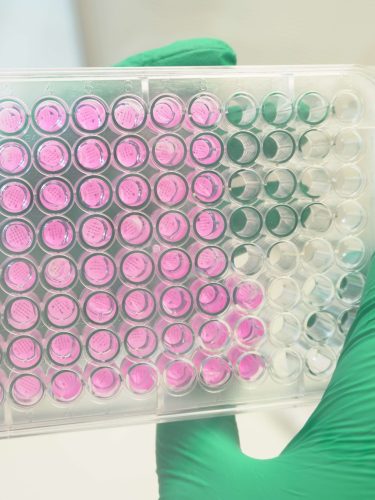

Bone tissue engineering in preclinical research

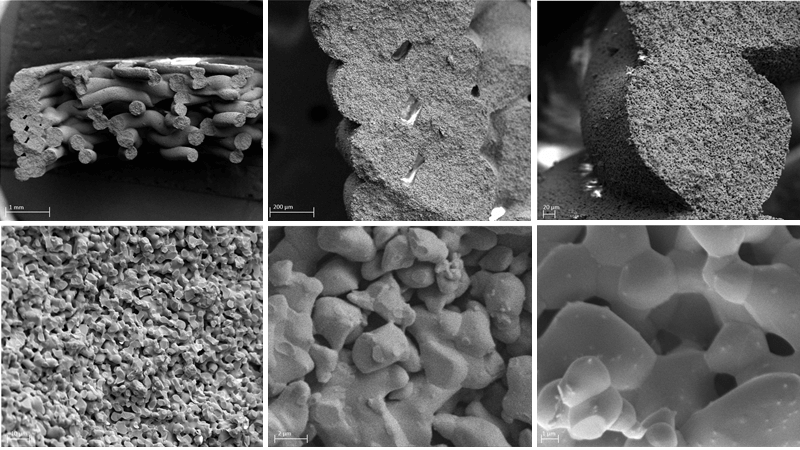

Ossiform’s expertise in medical 3D printing is further used to provide a research product line of natural bone-like environments wherein disease mechanisms can be studied and new treatments can be tested ― the P3D Scaffolds, 3D cell culture systems

SEM image of P3D Scaffolds. Picture courtesy of Luis Eduardo Carneiro-Campos, PhD.